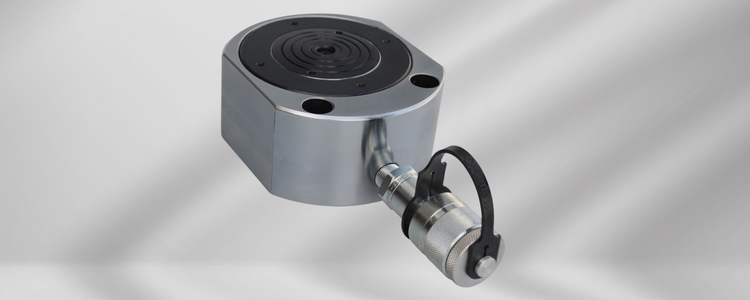

Hydraulic Flat Jacks Plain Ram Single Acting Spring Return Suppliers

Product Details:

Hydraulic Flat Jacks Plain Ram Single Acting Spring Return Suppliers Price And Quantity

- 5000.00 - 10000.00 INR/Piece

- 10000 INR/Piece

- 1 Piece

Product Description

Capacity 5 - 200 ton / Stroke 8 - 16 mm / Max. Working pressure 700 bar

| Capacity (ton) |

Capacity (kN) |

Stroke (mm) |

Model | Effective area (cm2) |

Oil cap. (cc) |

Closed height (mm) |

Wt. (Approx.) (kg) |

|---|---|---|---|---|---|---|---|

| 5 | 56 | 8 | OSF 5-8 | 8 | 6 | 35 | 0.6 |

| 10 | 111 | 12 | OSF 10-12 | 15.9 | 19 | 45 | 1.3 |

| 20 | 218 | 12 | OSF 20-12 | 31.2 | 37 | 55 | 2.6 |

| 30 | 309 | 12 | OSF 30-12 | 44.2 | 53 | 60 | 3.8 |

| 50 | 550 | 16 | OSF 50-16 | 78.5 | 126 | 65 | 6.2 |

| 75 | 792 | 16 | OSF 75-16 | 113.1 | 180 | 80 | 11.8 |

| 100 | 1077 | 16 | OSF 100-16 | 153.9 | 247 | 85 | 15.1 |

| 150 | 1589 | 16 | OSF 150-16 | 227 | 363 | 100 | 27 |

| 200 | 1985 | 16 | OSF 200-16 | 283.5 | 454 | 115 | 40.7 |

Advantages of Flat Jacks Single Acting

Flat Jacks Single Acting are hydraulic cylinders utilized for lifting, pushing, clamping, and supporting applications. Their low-profile design allows them to fit in tight spaces where conventional cylinders cannot. Some of the features of Flat Jacks Single Acting are:

- They have a single-acting piston that extends when hydraulic pressure is applied and retracts when the pressure is released.

- They have a spring return mechanism that automatically returns the piston to its original position when the pressure is released.

- They have a safety lock nut that prevents the piston from retracting accidentally and provides the mechanical load-holding capability.

- They have a hard chrome-plated piston rod that resists corrosion and wear.

- They have a high-strength alloy steel body that can withstand high loads and pressures.

- They have a wiper seal that protects the cylinder from dirt and contamination.

- They have a mounting hole on the base and the piston rod for easy installation and alignment.

Applications of Flat Jacks Single Acting

Flat jacks single-acting are widely used in construction, engineering, mining, shipbuilding, railway, and automotive industries. They can be used for tasks such as:

- Lifting of viaduct structures, bridges, and crane repairs

- Site maintenance and demolition

- Aligning and lowering heavy machinery

- Lifting of motors and generators

- Clamping of molds and dies

How to Use Flat Jacks Single Acting?

To use flat jacks single-acting safely and effectively, you should follow these steps:

1. Select the appropriate flat jack model based on your load capacity, stroke length, and available space requirements.

2. Connect the flat jack to a suitable hydraulic pump with a high-pressure hose.

3. Place the flat jack under or between the load to be lifted or moved. Ensure there is no gap between the jack and the load surface to utilize the whole stroke.

4. Apply pressure gradually by operating the pump until the desired position or movement is achieved. Do not exceed the rated capacity or stroke of the jack.

5. Release the pressure by slowly turning the release valve on the pump until the spring returns the piston to its original position.

6. Disconnect the hose from the jack and store it properly.

Flat jacks single acting are versatile tools that help you perform various tasks quickly and efficiently. However, they also require proper care and maintenance to ensure longevity and performance. You should always:

- Keep them clean from dirt, dust, and oil

- Lubricate them regularly with hydraulic oil

- nspect them for any damage or wear before each use

- Replace any worn or damaged parts immediately

- Follow all safety precautions when using them

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Hydraulic Jack' category

|

BEST HARDWARE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry