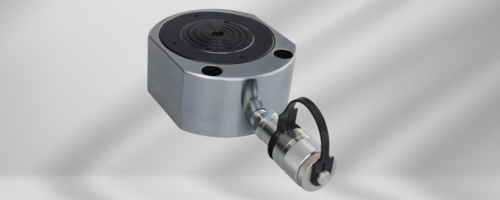

Hydraulic Cylinder Jacks General Purpose Plain Ram Single Acting Spring Return

Product Details:

Hydraulic Cylinder Jacks General Purpose Plain Ram Single Acting Spring Return Price And Quantity

- 15000.00 - 20000.00 INR/Piece

- 1 Piece

- 20000 INR/Piece

Product Description

Capacity 5-1000 ton / Stroke 50-200 mm / Max. Working Pressure 700 bar

| Capacity (ton) | Capacity (kN) | Stroke (mm) | Model | Effective area (cm2) | Oil cap. (cc) | Closed height (mm) | Wt. (Approx.) (kg) |

|---|---|---|---|---|---|---|---|

| 5 | 56 | 50 | OSP 5-50 | 8 | 40 | 135 | 1.3 |

| 5 | 56 | 100 | OSP 5-100 | 8 | 80 | 185 | 1.8 |

| 5 | 56 | 150 | OSP 5-150 | 8 | 121 | 235 | 2.3 |

| 10 | 111 | 50 | OSP 10-50 | 15.9 | 80 | 135 | 2.4 |

| 10 | 111 | 100 | OSP 10-100 | 15.9 | 159 | 185 | 3.2 |

| 10 | 111 | 150 | OSP 10-150 | 15.9 | 239 | 235 | 4 |

| 10 | 111 | 200 | OSP 10-200 | 15.9 | 318 | 285 | 4.7 |

| 15 | 167 | 50 | OSP 15-50 | 23.8 | 119 | 140 | 4.4 |

| 15 | 167 | 100 | OSP 15-100 | 23.8 | 238 | 190 | 5.4 |

| 15 | 167 | 150 | OSP 15-150 | 23.8 | 356 | 240 | 6.4 |

| 15 | 167 | 200 | OSP 15-200 | 23.8 | 475 | 290 | 7.4 |

| 20 | 218 | 50 | OSP 20-50 | 31.2 | 156 | 145 | 4.8 |

| 20 | 218 | 100 | OSP 20-100 | 31.2 | 312 | 195 | 6 |

| 20 | 218 | 150 | OSP 20-150 | 31.2 | 468 | 245 | 7.4 |

| 20 | 218 | 200 | OSP 20-200 | 31.2 | 623 | 295 | 8.6 |

| 25 | 270 | 50 | OSP 25-50 | 38.5 | 192 | 155 | 6.7 |

| 25 | 270 | 100 | OSP 25-100 | 38.5 | 385 | 205 | 8.4 |

| 25 | 270 | 150 | OSP 25-150 | 38.5 | 577 | 255 | 10 |

| 25 | 270 | 200 | OSP 25-200 | 38.5 | 770 | 305 | 11.8 |

| 30 | 309 | 50 | OSP 30-50 | 44.2 | 221 | 160 | 9 |

| 30 | 309 | 100 | OSP 30-100 | 44.2 | 442 | 210 | 11.5 |

| 30 | 309 | 150 | OSP 30-150 | 44.2 | 663 | 260 | 13.5 |

| 30 | 309 | 200 | OSP 30-200 | 44.2 | 884 | 310 | 15.5 |

| 50 | 550 | 50 | OSP 50-50 | 78.5 | 393 | 175 | 15.5 |

| 50 | 550 | 100 | OSP 50-100 | 78.5 | 785 | 225 | 19 |

| 50 | 550 | 150 | OSP 50-150 | 78.5 | 1178 | 275 | 22.5 |

| 50 | 550 | 200 | OSP 50-200 | 78.5 | 1571 | 325 | 26.5 |

| 75 | 792 | 50 | OSP 75-50 | 113.1 | 565 | 180 | 22 |

| 75 | 792 | 100 | OSP 75-100 | 113.1 | 1131 | 230 | 27 |

| 75 | 792 | 150 | OSP 75-150 | 113.1 | 1696 | 280 | 33 |

| 75 | 792 | 200 | OSP 75-200 | 113.1 | 2262 | 330 | 38 |

| 100 | 1077 | 50 | OSP 100-50 | 153.9 | 770 | 185 | 30 |

| 100 | 1077 | 100 | OSP 100-100 | 153.9 | 1539 | 235 | 37.5 |

| 100 | 1077 | 150 | OSP 100-150 | 153.9 | 2309 | 285 | 44.5 |

| 100 | 1077 | 200 | OSP 100-200 | 153.9 | 3079 | 335 | 52 |

| 150 | 1589 | 50 | OSP 150-50 | 227 | 1135 | 200 | 54 |

| 150 | 1589 | 100 | OSP 150-100 | 227 | 2270 | 250 | 65 |

| 150 | 1589 | 150 | OSP 150-150 | 227 | 3405 | 300 | 76 |

| 200 | 2199 | 50 | OSP 200-50 | 314.2 | 1571 | 215 | 71 |

| 200 | 2199 | 100 | OSP 200-100 | 314.2 | 3142 | 265 | 86.5 |

| 200 | 2199 | 150 | OSP 200-150 | 314.2 | 4712 | 315 | 102 |

| 250 | 2661 | 100 | OSP 250-100 | 380.1 | 3801 | 270 | 109 |

| 250 | 2661 | 150 | OSP 250-150 | 380.1 | 5702 | 320 | 126 |

| 250 | 2661 | 200 | OSP 250-200 | 380.1 | 7603 | 370 | 143 |

| 300 | 3167 | 100 | OSP 300-100 | 452.4 | 4524 | 285 | 141 |

| 300 | 3167 | 150 | OSP 300-150 | 452.4 | 6786 | 335 | 164 |

| 300 | 3167 | 200 | OSP 300-200 | 452.4 | 9048 | 385 | 187 |

| 400 | 4008 | 100 | OSP 400-100 | 572.6 | 5726 | 315 | 190 |

| 400 | 4008 | 150 | OSP 400-150 | 572.6 | 8588 | 365 | 217 |

| 400 | 4008 | 200 | OSP 400-200 | 572.6 | 11451 | 415 | 243 |

Features of General Purpose Jacks Single Acting

General purpose jacks single acting are hydraulic cylinders used for various lifting, pushing, or pulling applications in different industries. They have a plain ram that extends when hydraulic pressure is applied and retracts when released. They also have a spring return mechanism that helps to retract the ram faster and easier.

Some of the features of general purpose jacks single acting are:

- They have a wide range of capacities, from 5 to 1000 tons, and strokes, from 50 to 200 mm.

- hey have a maximum working pressure of 700 bar, which ensures high performance and durability.

- They have a compact design and low weight, which makes them easy to transport and store.

- They have a threaded collar for accessible mounting accessories such as tilt saddles, clevis eyes, or base plates.

- They have a chrome-plated plunger that resists corrosion and wear.

- hey have a safety valve that prevents overloading and damage to the cylinder.

- They have a wiper seal that protects the cylinder from dirt and contamination.

Applications of General Purpose Jacks Single Acting

General-purpose jacks single-acting are hydraulic cylinders that can produce a linear force by applying hydraulic pressure to one side of the piston. They have a plain ram that extends when pressurized and retracts by a spring or by gravity when the pressure is released. They are also known as spring return jacks or plain ram jacks.

General purpose jacks single acting is widely used for various industrial applications that require lifting, pushing, pulling, bending, spreading, clamping, or holding loads. Depending on the need, they can be mounted horizontally, vertically, or at any angle.

Some of the standard applications of general purpose jacks single acting are:

- Lifting and lowering heavy equipment, machinery, vehicles, bridges, buildings, or structures

- Aligning and positioning components during assembly, installation, or maintenance

- esting and calibrating load-bearing devices such as scales, presses, or cranes

- Applying tension or compression forces to materials or structures for testing or forming purposes

- Separating stuck or frozen parts such as flanges, gears, or bearings

- Clamping and holding workpieces during machining, welding, or drilling operations

How to Use General Purpose Jacks Single Acting

To use general purpose jacks single acting, you need to follow these steps:

Select the appropriate jack for your load capacity, stroke length, and working space. Ensure the jack is in good condition and has no leaks or damages.

Connect the jack to a hydraulic pump with a suitable hose and coupler. Assure the hose is not contorted or kinked and the coupler is securely fastened.

Place the jack under or against the load you want to lift, push or pull. Ensure the jack base and ram align with the load center and have a solid contact surface. Use saddle attachments if needed to prevent slippage or damage.

Open the release valve on the pump and pump oil into the jack until the ram reaches the desired position. Check for any signs of instability or overload on the jack or load.

Close the release valve on the pump and lock it if possible. Do not leave the pump unattended while under pressure.

To lower or retract the ram, open the release valve slowly and carefully until the oil flows back into the pump reservoir. Wait to let go of the valve until the ram is fully retracted.

Disconnect the hose from the jack and drain any excess oil from the cylinder. Store the jack in a clean and dry place.

General purpose jacks single acting are simple but powerful tools that help you with various lifting, pushing, or pulling tasks. However, they also require proper care and safety precautions to avoid accidents or injuries. Always follow the manufacturer's instructions and specifications when using hydraulic jacks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Hydraulic Jack' category

|

BEST HARDWARE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry